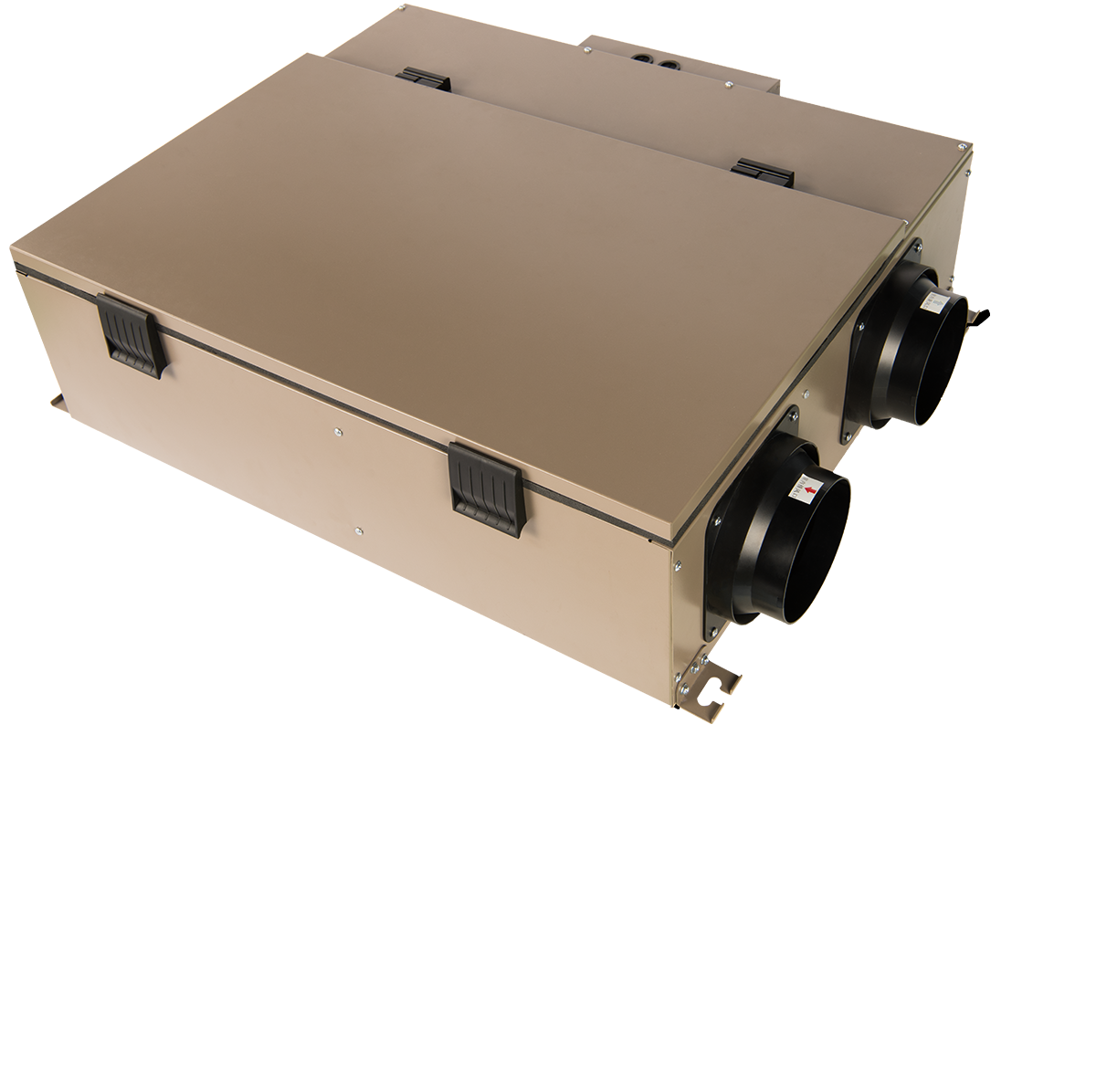

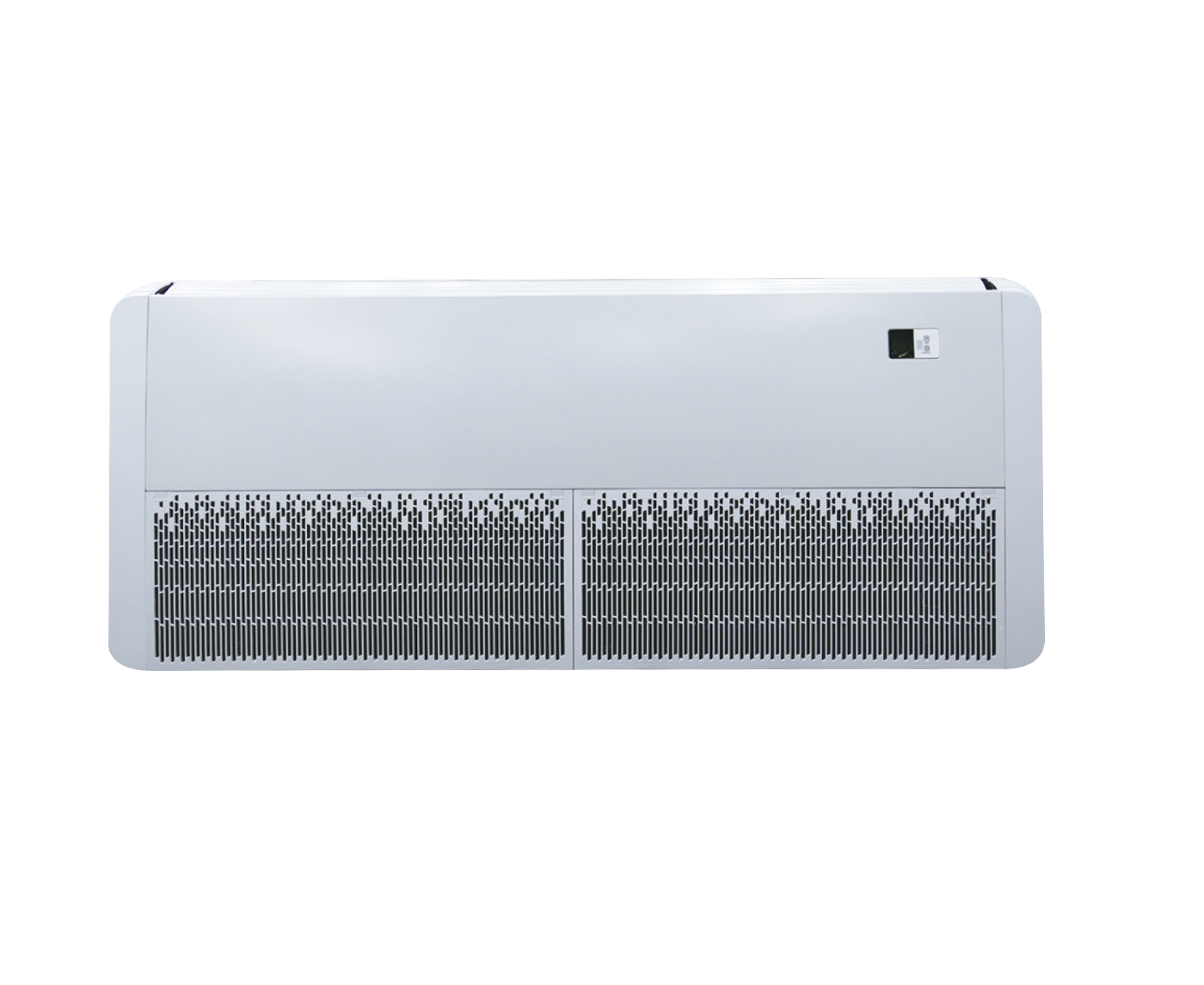

Constant airflow ducted units are often used with the highest efficiency systems and are designed as a true variable speed system. As static pressure changes in the system, the load on the blower adjusts. If the filters or evaporator coil gets dirty, the static pressure increases, resulting in less air movement and less load on the motor. The constant airflow inverter motor increases its speed to make up for the loss of air.

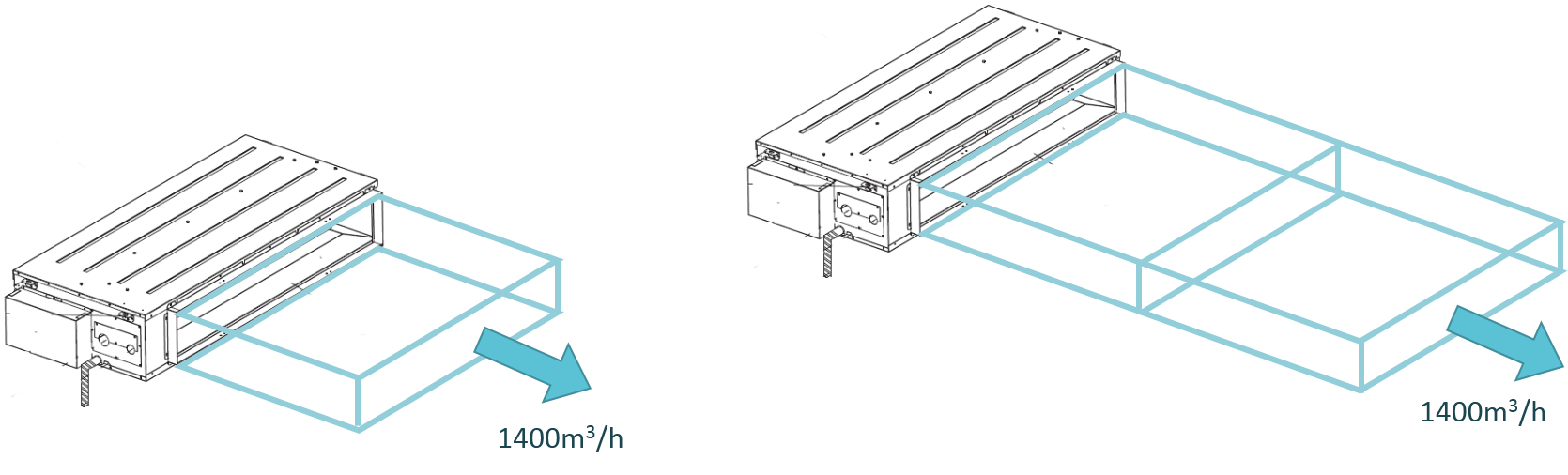

GCHV has launched its 200Pa inverter constant airflow ducted unit with R-32. The unit is available in both 24K and 36K Btu/H capacities with CE and ErP certification. The 48K and 60K Btu/h units will be available soon. These units include a DC inverter brushless fan motor, enabling the constant airflow supply, and the maximum static pressure up to 200Pa. Airflow will not decrease even if the external static pressure (ESP) increases. For the 24K Btu unit, the airflow is 1400/1200/1000m3/h and for the 36K Btu unit, the airflow is 1950/1650/1350m3/h. Air return from rear or bottom is easily changed according to the actual project application.

The fan speed automatically adjusts to meet different ESP requirements with different duct lengths. A wired controller for an auto airflow adjustment setting can be used.